Diacetyl rest is an important part of the brewing process. In this article, we’ll answer the question, “What is a diacetyl rest?” and discuss how it improves your homebrew.

Off-flavors in homebrew happen a lot. Even experienced homebrewers deal with batches that end up with a funky taste. Sometimes these funky tastes have a specific cause and solution, other times you’re just left wondering what happened and starting over.

If you are like us and are just learning to lager, you may discover that your beer tastes fine after primary fermentation, but after conditioning, it tastes like microwave popcorn.

The cause of this buttery flavor is diacetyl. And believe me when you get an abundance of diacetyl in your beer, you’ll know. This buttery off-flavor is quite distinct and can really kill a great beer.

The problem with diacetyl is that it doesn’t make its flavor appearance in your beer until after primary fermentation is complete and you’ve either started secondary fermentation, or your beer is in your kegerator and ready to drink.

At this point, there is no solution to diacetyl in your beer, besides dumping it or sucking it up and drinking it anyway.

You can prevent diacetyl in your beer, and when you’re making a lager the best solution is to do a diacetyl rest. What is a diacetyl rest you may ask? Well, read on for all the details on this often-skipped step in homebrewing.

What the Heck is Diacetyl?

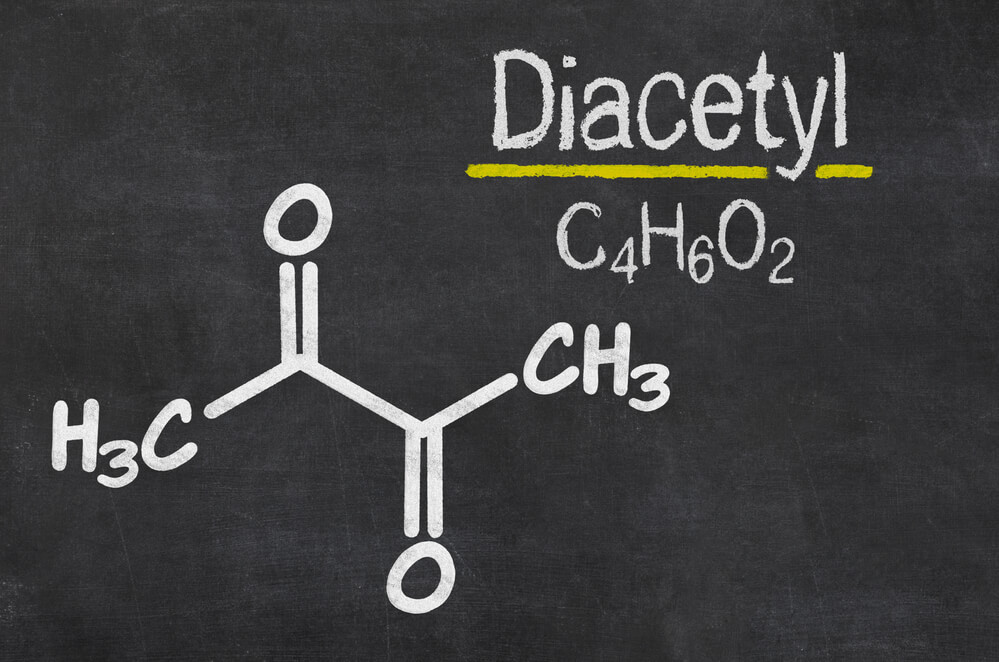

Before we talk about how to get rid of diacetyl, it is helpful to know what it is and where it comes from.

Believe it or not, diacetyl is a natural byproduct of the fermentation process. Most beers have a bit of diacetyl, but because the amount is so small, you won’t taste it. Some beer styles and even specific beers rely on diacetyl for their distinct flavor.

One of the most popular beers that has an abundance of diacetyl which creates its trademarked flavor is Redhook Brewing’s ESB.

Diacetyl is formed during the growth phase of yeast when acetolactate is oxidized. This reaction occurs when fermentation temperatures are higher. If the fermentation temperature is maintained at this warmer point (65 to 70 degrees Fahrenheit) the yeast will consume the diacetyl and hold onto it until you separate the beer from the yeast slurry.

When we lager a beer, we reduce the fermentation temperature, and at lower fermentation temperatures, the yeast will not consume the diacetyl that they’ve produced, and the diacetyl remains in your beer, making it taste wrong.

Diacetyl Rest Saves the Day

The best solution for eliminating or at least significantly reducing diacetyl in your lagers is a diacetyl rest. It seems technical, but a diacetyl rest is really simple, and can make a huge difference in your lager flavor. Here’s how it works:

- As your beer gets close to the end of fermentation with only about 5 gravity points to go, warm the fermenter to as close to 68 degrees as possible. Use a fermenter heater or wrap for this step.

- Allow the beer to sit at this higher temperature for at least two days or until the correct final gravity has been reached.

- Test the beer for final gravity, and sample a small amount to determine if diacetyl has been reduced and there is no off-flavor.

- If you notice that the beer still has an off-flavor, continue to ferment for another two or three days to fully reduce the diacetyl.

- If you are making an ale, you can keg or bottle at this point. If your beer is a lager, you can move to the cold conditioning step.

4 Tips for Preventing Diacetyl in Beer

Even though diacetyl is naturally produced by yeast, this is not the only way that it can show up in your beer.

Contamination, insufficient aeration, insufficient nutrients for yeast, and even the type of yeast you are using can contribute diacetyl to your beer. Here are some tips for reducing or eliminating diacetyl in your final product.

- Use a different yeast strain. If you use a single strain of yeast and it consistently produces a buttery taste, try a different yeast.

- Make sure you aerate your wort sufficiently prior to fermentation. Lack of oxygen can stress yeast and cause it to not consume diacetyl. Pure oxygen is the best solution.

- Use a yeast nutrient if you suspect your beer is lacking in an adequate nutrient supply.

- Clean and sanitize all your equipment thoroughly. Contamination from bacteria or native yeasts can cause diacetyl production.